STRI World Cup Bulletin

Dave Kirkby and his team of turf professionals at Topturf know a thing or two about working to exacting standards. It was Topturf that constructed the Gary Player Country Club's golf course 30 years ago - the first layout in South Africa to conform to USGA specifications. Topturf has maintained South Africa's Number one ranked golf course since it was first unveiled, and it is generally accepted that the standard of the conditioning of Sun City's famous course is the yardstick by which others are measured.

But nothing prepared anyone for the attention to the most minute detail that was required for our pitches to pass FIFA's quality standards.

"In terms of turfgrass management, the construction, renovation, maintenance and preparation of more than 80 football pitches prior to our hosting of the World Cup would be difficult to eclipse," says Kirkby. "I'm sure that most turf contractors and turf consultants were under the illusion that presenting a little better surface than that for a Super 14 rugby game was all that was required. "Anyone not familiar with the stringent specifications placed by FIFA on pitches could have been forgiven for believing this, considering that our premier rugby venues are not exactly shabby.

"The 2009 Confederations Cup turned that idea right on its head", he says explaining that three rugby stadia pitches - Ellis Park, Loftus and Bloemfontein - were noted as needing improvement for international competition. "Only the Royal Bafokeng Soccer Palace came anywhere near the standards required," he adds. What needed to be improved?

Pitch Levels

The playing surface had to be laser level smooth for the World Cup match pitches. The tolerance needed to be six millimetres over a three metre straight edge. That is more stringent than a tar road surface.

Pitch General Shape

Pitches had to have a domed shape with slopes in four directions of between 0.6% and 0.7%. This assisted surface drainage.

Surface Stability

With most pitches being sand-based, they required the top 100 mm to be reinforced with artificial fibre. Local stadia have been reinforced with Netlon, StaLock or Desso.

Grass Species

All pitches had to be 95% ryegrass. This required converting all the warm season pitches to ryegrass and establishing with pure ryegrass in Cape Town.

Irrigation

The irrigation system needed to be infield pop-ups as opposed to external big guns. This allowed the pitch to be syringed for two to four minutes prior to and during practices and matches.

Renovation

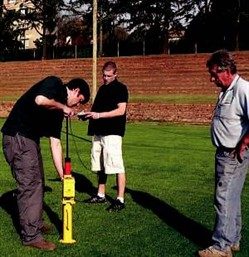

In February/March, the pitches all had to receive a major renovation makeover.

This involved:

- Removing the surface by fraise mowing at minus 10 mm

- Hollow tining/Verti-Draining

- Sand top dressing and drag matting

- Seeding with ryegrass

All of this, 90 days or less before the teams arrived.